From the Workshop 1: Ground Control Station

A blog by Marwan Hussein, Balint Magyar, and Andrea Nardi.

Having originally started off as another tool in the military’s inventory, drones have come a long way since their inception, eventually even finding their way into the hands of hobbyists, racers, and various industry giants. With new drones being introduced to the market on a near yearly basis, it is often that this influx of shiny new models overshadows any advancements made in ground control station technology.

Ranging in size from something that fits in the palms of your hands to an entire shipping container, we spoke to two of our engineers working on our upcoming ground control station, Andrea and Balint, to understand how it all comes together. In this article, we will talk a bit about the basics of ground control stations, explain how they communicate with our (or any) flight controller, and how our upcoming Ground Control Station software (GCS) and flight controller will pair to accommodate your drone platform into tomorrow’s uncrewed infrastructure.

A: Andrea B: Balint

How information is exchanged between the GCS and the drone.

From the ground

Regardless of the size of the ground control station being used, the fundamentals of operation for all kinds remains the same; the operator must be able to control the flight direction/mission of the drone, manage any onboard payloads, monitor the drone’s status, and transmit information to and from their platform through a communication system. The ground control station can be a computer or a smartphone which bi-directionally communicates with the drone to control and monitor the drone flight.

B: “Some ground control software also provide features specific to the type of drone they are meant to connect to, for example a companion controller for a camera drone might offer media management or live camera footage, or a survey drone might offer ways to view and work with sensor data collected during the flight.”

With regards to exchanging information between the ground control station and your platform, communication normally occurs using radio waves. One of the most common types of communication protocols used in the drone world is MAVlink.

B: “MAVlink is a standardized communication protocol for talking to UAVs. It’s basically a shared language between most drones and ground control software. It defines in what format the drone should broadcast its data (telemetry, system status, camera feed, etc.) and also defines how control software should issue commands to the drone.”

Not only is MAVlink used to transmit information from the drone to the ground control station and back, it is also used to communicate between onboard components. With a proven track record on a plethora of vehicles since 2009, it is preferred over other types of protocols due to its high efficiency and reliability.

From the air

Diving a little deeper into MAVlink, what would this connection look like from the flight controller’s end?

A: “In short, MAVlink specifies the meaning of each byte that is sent and received. This means that any communication channel that supports a binary format can be used to send and receive MAVlink messages. Some common channels for MAVlink communications is User Datagram Protocol (UDP) and serial. Currently, both the Fusion Reflex and our own upcoming ground control station support UDP and serial MAVlink communications.”

In a dynamic environment where anything can occur in the blink of an eye, it is equally important to maintain a high rate of accessibility between devices; One of the advantages of using UDP is that no overhead needs to be established to transmit messages beforehand, drastically speeding up connectivity. Furthermore, not being constrained to a 1-to-1 communication configuration gives it the added benefit of broadcasting information to multiple ground control stations. Conversely, this can also allow multiple drones to communicate with a single ground control station, enabling an additional dimension of fleet management.

Fusion Engineering Ground Control Station

Having already completed several successful tests with our maiden product, the Fusion Reflex, we decided to also pursue the design of our own ground control station to go with it! Due to the large volume of information being exchanged between the Fusion Reflex and the ground, the focus of development was centered around creating a fully compatible GCS-FC combination.

So what do we mean by full compatibility?

A: “Continuing on the MAVlink topic, this protocol requires a reciprocal understanding of the messages being exchanged. By implementing our own software for both the FC and the GCS, we can assure that every message that is being exchanged is understood by both devices. Additionally, this gives us the flexibility to give the GCS its own dialect, improving security further as well as supporting a plethora of additional sensors.”

One of the advantages of creating our own control station from the ground up is the ability to build it using the modern “React” library in a web application. While it is not a novel idea in itself, utilizing a familiar and matured technology to develop the User Interface (UI) makes it more accessible for a wider user audience of all experience levels. This approach is adopted by several applications and companies that you probably have heard of, such as Microsoft Teams, Spotify, and Discord to name a few.

Having talked about “Rust” in the past, we once again find it to be highly relevant in applications that extend beyond just within our flight controller; By programming our ground control station’s software using a combination of “Rust” for low-level operations and “Typescript” for higher-level interfaces, the UI can maintain a high level of robustness and speed, just as it does in the Fusion Reflex.

A: “”Rust” is usually less memory-hungry and more performant compared to other programming languages, which overall allows a more responsive UI. Additionally, many low-level networking functions and binary manipulations are more adequate in a “bare bone” programming language like “Rust”, with some of the binary manipulations being the handling of MAVlink messages to and from the flight controller.”

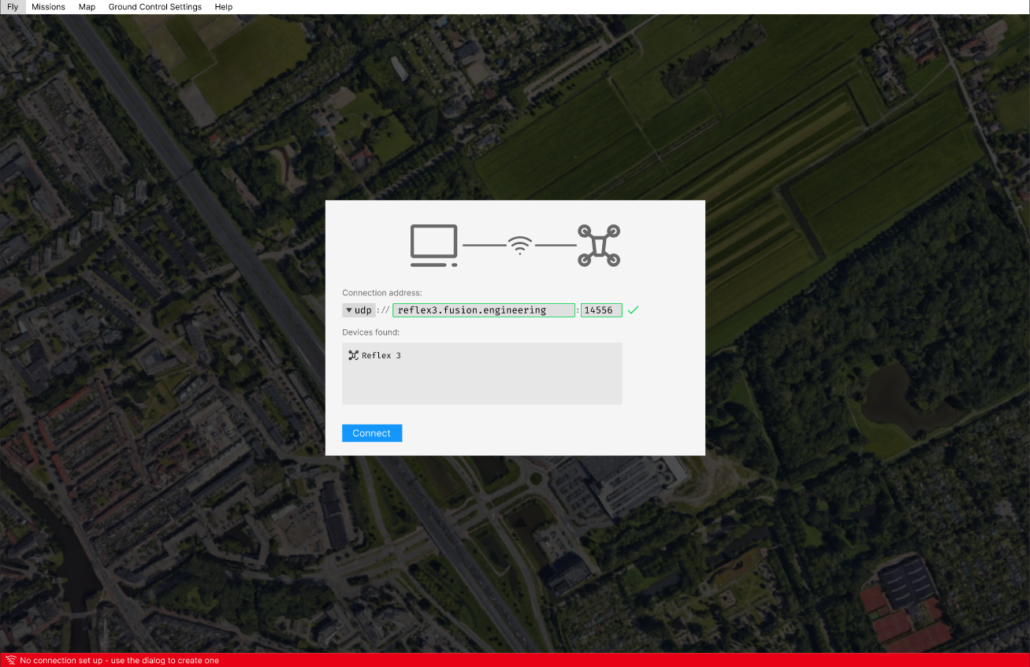

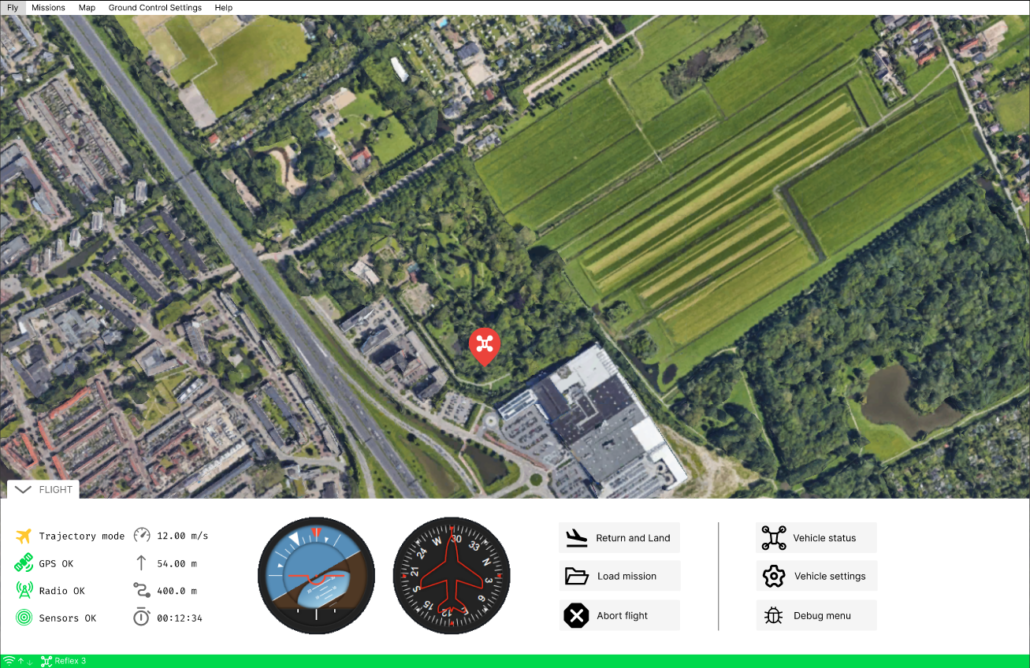

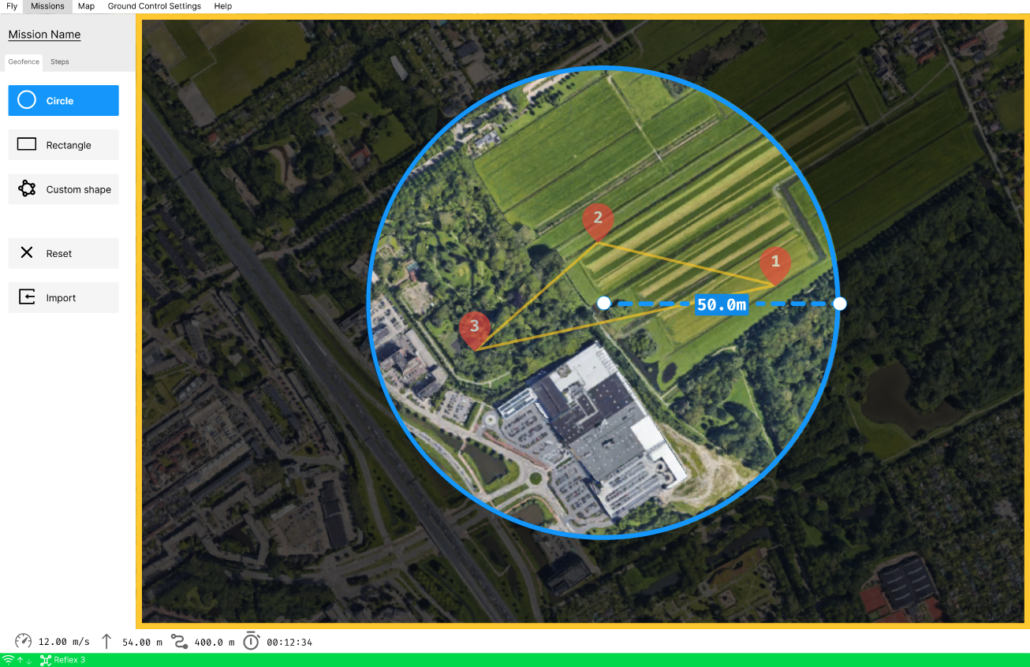

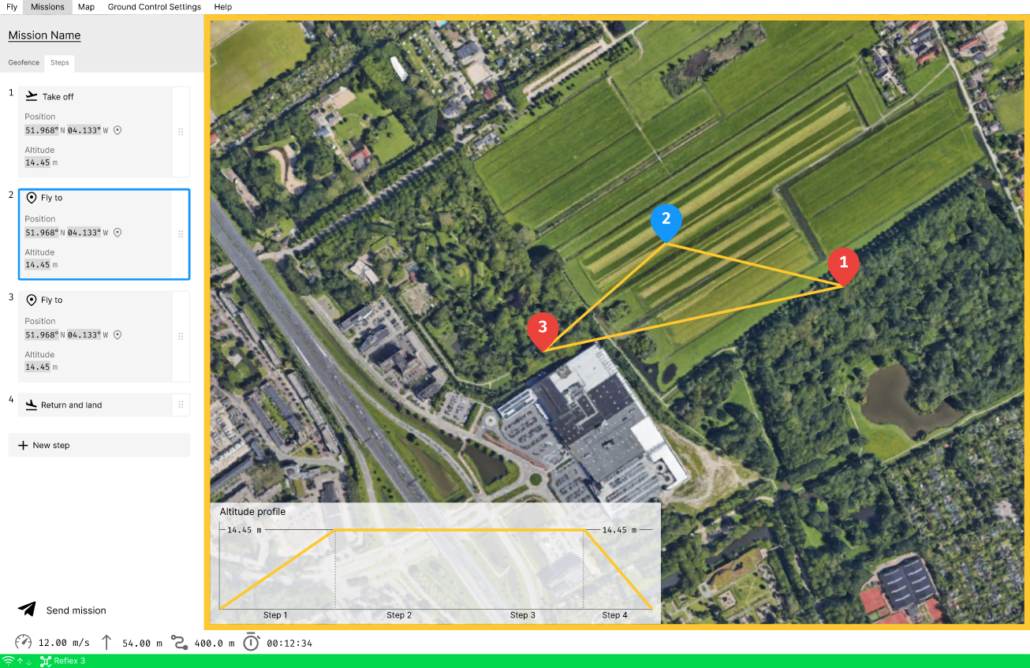

So what will all of this look like? Take a peek below at a few teaser images of the UI that has been in the works by our ground control station team:

Straight away, you are greeted with a window that displays your nearby discoverable Reflexes. We opted for an interface that would already look familiar and easy to navigate, hence the smartphone-like layout.

Once connected, a bird’s-eye view of your drone’s location is pinpointed. A user-friendly instrument panel is displayed in the bottom half of the screen showing information on your drone’s attitude, speed, and location to name a few. This panel can also be collapsed to give you an unobstructed view of your area of operations.

For reasons that could relate to flight regulations, restrictions, or even automation, a “geofenced” area may be required to make sure the drone does not stray too far away. Drawing this area can be done with a variety of pre-sets and custom shapes.

When it comes to the flying, this can be done via a series of commands that are very easy to manipulate and shuffle. The operator can compile a mission for their platform by simply designating areas on the map and inputting basic flight parameters.

Complemented by the Fusion Reflex’s support for local coordinate systems as well as the ground control station’s capability of being used offline, flights can be planned in GPS-denied locations, enabling indoor flights where connection is weak or non-existent. Furthermore, the GCS will be able to act as a relay for external high-precision positioning systems, significantly facilitating and automating their setup.

Despite this being an early version of what we are aiming to release, the elements that we want to capture in all iterations are user-friendliness, simplicity, and familiarity. We understand that, especially with BVLOS flight being the main form of drone operation, users want a steady and reliable influx of high-fidelity information on what their drone is doing and where it is at all times.

How will the Fusion GCS-FC combination fit within the wider uncrewed framework?

U-Space

Undoubtedly, we initiated the development of our first ground control station with tomorrow’s uncrewed operations ecosystem in mind.

One of the hottest topics circulating the drone industry is Uncrewed Traffic Management (UTM). Similar to existing air control towers, UTMs will become the base infrastructure within which, ultimately, flight corridors are to be defined to allow drones to safely execute their missions.

Taking EASA for being Europe’s governing air traffic authority as an example, a set of new services is being established to support the flight and operations of high volumes of drones in a specified airspace. This is called U-Space.

EU member states will be able to designate specific no-fly zones and geofenced areas, whereas the handling of the actual services happens through a commercial U-Space Service Provider (USSP). Every USSP is in turn required to provide at least the following four services:

- Geo-awareness

- Traffic Information

- Flight Authorization

- Network Identification

Optional services including:

- Weather Information

- Conformance Monitoring with the U-Space Requirements

With the U-Space technology and proposed regulation heavily relying on the digitalization, automation, and sharing of information between all airspace users, it is important to ensure an equally-robust coordination between all ground stations and their corresponding drones is maintained.

Iris Automation Casia Detect & Avoid System.

Detect & Avoid

Complimentary to UTM, Detect & Avoid (D&A) systems are devices that, in principle, collect real-time information about the drone’s surroundings, which is then processed to determine the safest flight course for collision avoidance.

Ranging from radar to optical-based devices, D&A systems feed the collected information from their surroundings into the flight controller on the drone, which then translates this input into individual motor speeds and drone motion.

Primarily, however, D&A will act as a secondary safety net which overrides trajectory waypoints and commands the drone to move away from imminent danger. Coupled with our flight controller’s inherent stability improvement, this will also give drones the added benefit of flying in closer proximity to each other, enabling a wider variety of large-scale operations that involve formation-flight and fleet operations. For that reason, we have been developing the Fusion Reflex with the necessary variety of drivers to accommodate some of the industries most preferred D&A systems and sensors, all of which will be able to be configured and calibrated via the ground control station itself.

Fleet Management

Lastly, Fleet Management. As UAVs become more relevant by the day, it would not be long before they are confidently and routinely utilized in large commercial scales. Consequently for the operator on the ground, this means that a large amount of documentation must be handled and stored for reasons relating to transparency, traceability, and management. Therefore, an accessible and large storage infrastructure, such as cloud-based systems, would be preferred for such applications.

Another important element for running and enhancing your fleet operations is mobility; The ability to manage and monitor ongoing missions while on the go helps in streamlining quality control, maintenance, efficiency, and even team cohesion.

With governing air authorities demanding that drones are maintained in pristine condition at all times, methods that facilitate the health monitoring of individual components on the drone will play a detrimental role in maximizing safety and regulation compliance.

In summation, these are some of the elements that we wish to embody in our upcoming GCS software as well as our flight controller. Our goal at Fusion Engineering is to not only to provide you with the best control in the air, but also on the ground.

Have you operated a ground control station before? Or you’re an experienced drone operator? We would love to talk to you! Leave us a message with your feedback at contact@fusion.engineering!

Make sure to stay tuned in the development of our GCS by following us on LinkedIn and subscribing to our Newsletter!